29.07.2020

Manufacturers need resilient chains to withstand external shocks. Some shocks can be anticipated (Brexit, for example) whereas others are an unprecedented surprise (Covid-19). A smart, resilient supply chain is flexible enough to adapt and respond to these events, ensuring the flow of goods and materials is not significantly disrupted.

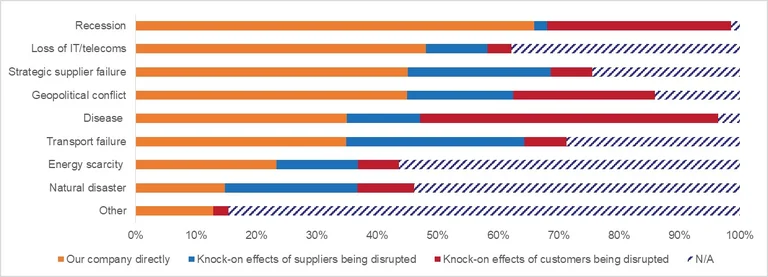

A recession is the biggest threat to manufacturers

66% of manufacturers believe that recession will disrupt their company in the next two years. 31% said there would also be knock-on effects for their customers.

The latest data suggests that most economies will face recession due to Covid-19, meaning that supply chains will be hit at all levels. Interestingly, only 2% of manufacturers thought a recession would have a knock-on impact on their suppliers. This may be because of a belief in a V shaped recovery. It is likely however that supply chains will be slow to restart as consumer and commercial demand gradually picks up.

But a recession isn’t the only threat

48% of manufactures reported loss of IT or Telecoms, for example through a cyber-attack, as a threat. Increased digitisation and connectivity between global suppliers increases manufacturers’ potential exposure to cyber-attack. This threat must be managed so that it does not put manufacturers off investing in digitalised supply chain networks.

Graph 1: In the next two years, where specifically do you think the following issues will disrupt your company?

Source: Make UK / Oracle survey, June 2020

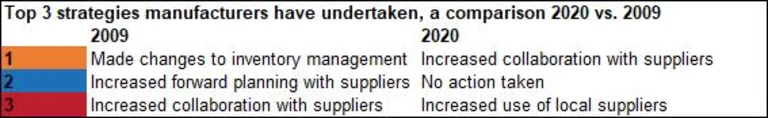

Increased collaboration builds resilience

Increase collaboration with suppliers is the most common strategy manufacturers have used to increase performance. Good visibility and clear communication with suppliers is critical. This is a marked change from what manufacturers said in 2009, where changes to inventory management was the most popular response.

Source: Make UK / Oracle survey, June 2020

Diversification and localisation

The results also show that manufacturers are diversifying their supply chains, with 15% using multiple suppliers. 15% also reported that they are increasing their use of local suppliers.

Being able to draw on multiple suppliers in different locations helps to reduce disruptions by spreading the risk. It can also increase agility as there are more supplier options to draw from.

Companies have to balance the efficiency offered by streamlined supply chains with the risk of a single point of failure bringing the entire supply chain to a halt. Tipping the balance further towards diversification will help manufacturers and the sector as a whole become more resilient, agile and responsive.

Is the digital opportunity being missed?

Connected and agile supply chains rely on data. So it’s surprising that the survey shows relatively low investment in developing digital solutions to monitor supply chain performance. This suggests that the opportunity to increase resilience by implementing data-driven supply chains is being missed by some manufacturers.

This is part of a larger picture we see from Make UK members, where there is a realisation that introducing the right technologies can increase resilience. However, some companies struggle to prioritise this investment, especially during difficulty times, which may have a negative impact in the long term.

New threats, new solutions

This survey has shown that the threats manufactures face are changing. Who would have put recession at the top of their risk register in January? Who would have been worried about a global pandemic this time last year?

As the threats change, so do manufacturers responses to them. It’s clear that manufacturers are prioritising connectivity and diversification as ways of reducing risk. With increased investment in technology, UK manufacturers can further develop smart, resilient supply chains that can withstand external shocks.

Oracle and Make UK have also delivered a webinar on the findings from our manufacturing smart supply chains blog series, including what lessons we can learn from previous geopolitical crisis, as well as best practice to help build resilience into your company’s supply chains.

Watch the full webinar here