The 4th industrial revolution

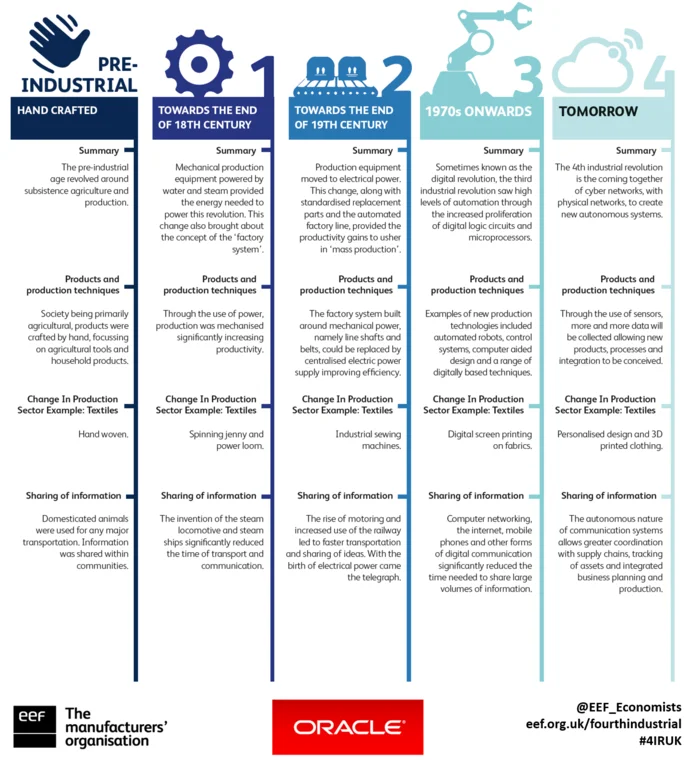

New digital technologies are changing UK manufacturing as part of the 4th industrial revolution (4IR), with 80% of manufacturers saying 4IR will be a business reality by 2025. These changes come alongside previous iterations of manufacturing which we explored in our 4IR factcard.

These technologies will drive the connectivity between physical networks and cyber networks to create one system to allow real-time information flow between the two. This will allow insights across a manufacturing business to be identified and acted on more quickly.

These insights may include the operational efficiency of a machine and the factors that may determine peak performance, augmented intelligence saving time in, say, warehousing, or machine to machine communication across supply chains to match production rates and minimise inventories.

Manufacturers view the benefits of 4IR as helping to deliver greater value to customers achieved through improved productivity and competitiveness. With this transformation happening right across the world, getting investments in 4IR happening will be crucial to ensure UK manufacturing remains competitive post-Brexit.

But is it hype though?

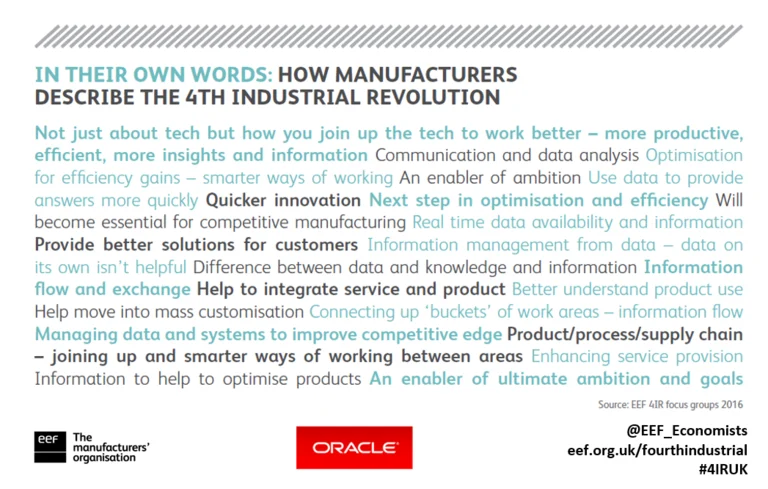

We’ve been engaging with our members over the last few years to understand what they are investing in and what they think this can achieve.

Our latest research data (which we’ll publish soon – watch this space) shows that there are some investments already happening in new technologies, but 4IR will be a journey of three phases, with most manufacturers at the early conception phase – i.e. trying to figure this all out.

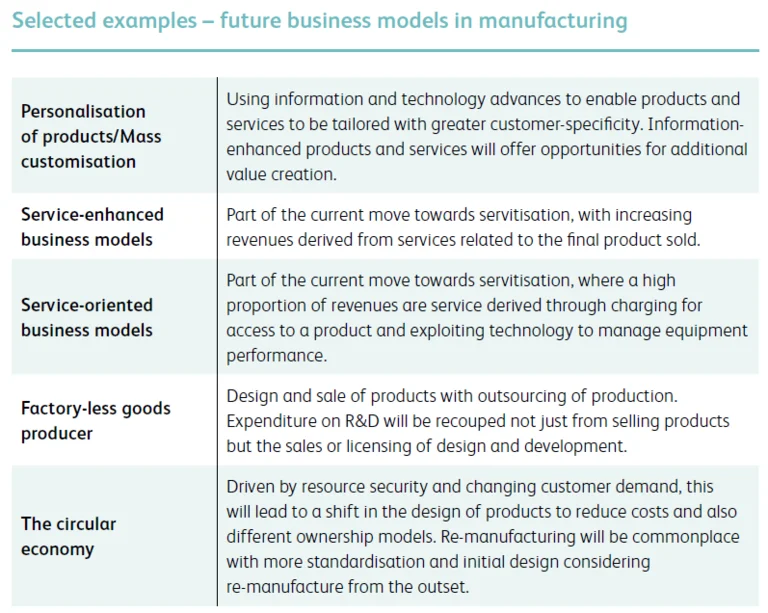

This will be followed by an evolution phase where current business practices are optimised by using insights from 4IR technologies before a final phase which will see a step change in how manufacturers use new business models to capture value using 4IR technologies and principles.

Read next: Optimising your business – White Paper on the 4IR ‘Evolution’ Phase

There are early 4IR investments being made

The chart below from our fact card highlights this, with some enabling technologies for wider 4IR investment, such as cloud solutions, topping the list.

But other technologies that are important such as augmented reality sit further down the list. Later this year we’ll be publishing how these numbers have changed over the last two years.

The barriers holding back 4IR investment

This underinvestment in some areas could be down to barriers holding companies back, our previous survey showed only 11% of manufacturers think ‘the UK manufacturing sector is geared up to take advantage of 4IR’.

Our 4IR primer report went into this in detail, but in summary the main barriers stem from:

- Lack of understanding about what this can deliver and therefore an inability to quantify a return on investment. This may explain why some technologies which are easier to understand are being invested in.

- Worries around the interoperability of data across platforms, the security of data and who owns that data, particularly where new business models have been applied.

Pushing through the barriers

There are things manufacturers could be doing like adapting their business culture around innovation, bringing IT from the back office to front and centre (or where they don’t exist recruiting staff with digital skills into the business) and providing leadership to drive through change.

Given the interconnected nature of manufacturing, there will also need to be this culture embedded in companies across supply chains for future technologies to deliver the competitive advantage and step change in performance that can be achieved.

A role for government

But there are things government could do to help and the industrial strategy, with its focus on productivity, will be crucial to this. We’ve previously written before on the urgent actions government must take on the strategy before mid-July (such as creating the independent Industrial Strategy Council), but looking across the 5 foundations of the strategy:

- On ideas: Sign off on the Industrial Strategy Challenge Fund for industrial digitalisation, ensure the UK remains a part of EU R&D collaborative frameworks and look again at the tax treatment for capital investment.

- On people: Deliver a skills system that is future focused and ensures lifelong learning and retaining by focusing the National Retraining Scheme on supporting existing employees to up-skill and re-skill, using technology to deliver flexible forms of learning demanded by employers and employees and embedding future skills into the education curriculum.

- On infrastructure: Step up plans to deliver full-fibre digital infrastructure across the country.

- On business environment: Work is ongoing, with the Business Productivity Review rightly highlighting the importance of technology diffusion to improving productivity. But work also needs to happen to look at the regulatory frameworks needed to enable new technologies – wasn't that a role for sector deals?

- On places: Tying Local Industrial Strategies to Grand Challenges to give them focus on how manufacturers and by extension 4IR, can help to put Britain at the forefront of the data revolution.

How you can help

Over the course of this year we’ll be publishing more work on 4IR, going into more detail on some of the technologies that can make a difference to manufacturing. If you’d like to share your insight or case study on how new digital technologies are transforming your business we would love to hear from you. Get in touch: [email protected]